Blowdown Valves

We offer a wide range of high-quality blowdown valves and other parts to ensure efficient and reliable operation of your system. Whether you need replacement valves, fittings, or other components, we have you covered.

With over 45 years of experience in the industry and a commitment to customer satisfaction, you can trust us to provide you with the right parts for your boiler system. Let’s keep your boiler running smoothly.

Call (714) 897-1036 or request a quote to get started.

Serving All Of Southern California

Parts for Commercial and Industrial Boilers

When it comes to commercial and industrial boiler parts, DB Sales & Service is your trusted source. We understand the unique needs and demands of commercial and industrial boiler systems, and we offer a comprehensive selection of parts to keep your operations running smoothly.

From burners and controls to pumps, valves, and heat exchangers, we have the parts you need to maintain and optimize your boiler system.

Our team of experts is here to assist you in finding the right parts for your specific requirements, ensuring that you receive top-quality products that meet the highest standards. With our extensive inventory and commitment to customer satisfaction, you can rely on us for all your commercial and industrial boiler part needs.

Request a Quote for Part(s)

DB Sales & Service can also help you with:

Purchasing new equipment

Repair/Maintenance by Factory Authorized Technicians

Retrofitting an old boiler with a new one that is compatible with your system

Rental boilers for immediate installation

View all the boiler parts that DB Sales carries.

What is a Blowdown Valve? The Ultimate Guide

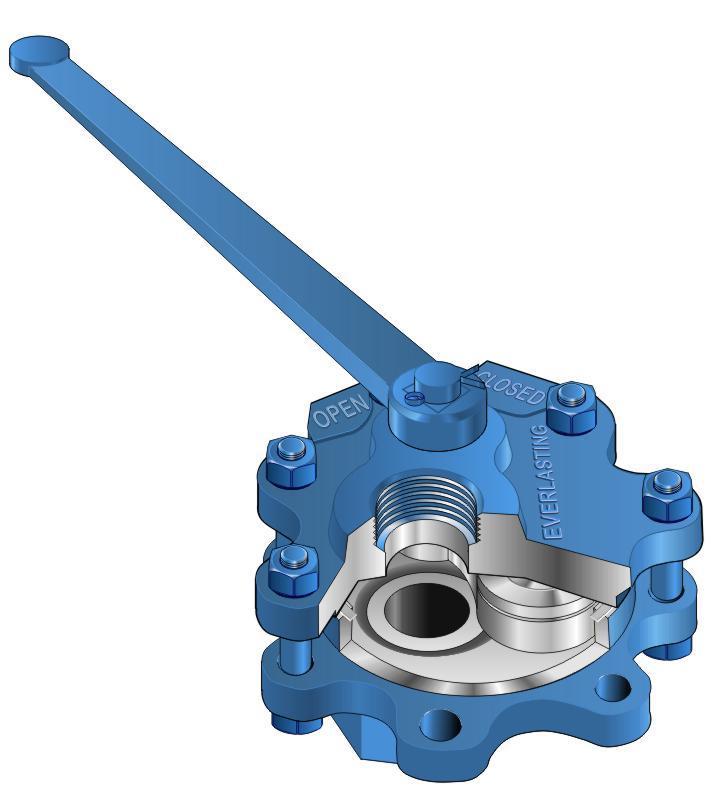

A boiler blowdown valve is an essential component of an effective boiler system. Designed to improve efficiency and safety, these valves help to manage the removal of sediment and impurities from your system, reducing the risk of scale buildup, reduced performance, and costly damage.

For commercial property owners, choosing the right blowdown valve can be the key to extending the life of your system, reducing operational costs, and adhering to crucial safety standards.

Drawing on our extensive experience in the boiler installation and equipment space, we created this guide to show you what blowdown valves do, how they work, and the different types available, to help you make the right choice for your building’s needs.

What is a Blowdown Valve?

A boiler blowdown valve is a component within industrial commercial and boiler systems used to remove contaminants like sediment, sludge, and other impurities from your system. These contaminants occur naturally in a boiler over time, thanks to the dissolved solids in the water your boiler uses for steam and heating operations.

Over time, if impurities build up within commercial or industrial steam boilers, they can lead to scaling, corrosion, and blockages. This harms the efficiency of the boiler, and can even lead to system failures. Blowdown valves keep boilers working effectively by consistently purging unwanted materials from the boiler. A control valve opens periodically to release a specific amount of water and contaminants from the system, minimizing the risk of dangerous buildup.

The concept of “blowdown percentage” is integral to this process. It refers to the proportion of water that is discharged to control the concentration of impurities. Typical blowdown percentages range from 4% to 10%, depending on the feedwater quality and the specific requirements of the system.

Systems using high-quality water with fewer dissolved solids may operate at the lower end of the range, while those with harder water or higher impurity levels may require more frequent or substantial blowdown.

Working Principle of Blowdown Valves

While boiler blowdown valves come in different forms, they’re all designed to effectively and efficiently remove contaminants from steam and water systems, ensuring longevity, smooth operation, and higher levels of energy efficiency. They work based on a controlled sequence of “opening and closing” processes intended to purge impurities while maintaining adequate boiler water levels.

When boiler pressure builds up in a system, often as a result of contaminants, a seal valve opens slightly to relieve that excess pressure. Once the environment is “stable” the main valve opens, allowing for a rapid discharge of water and impurities. This tandem operation helps to minimize damage and erosion caused by high-velocity water heating the valve seat directly.

After the system is “purged”, the valve closes firmly, but is often briefly re-opened to clear any debris that might be trapped during the process, preventing potential damage.

Notably, blowdown valves are specifically designed to handle the significant pressure and high temperatures found in steam systems. They feature specific components, such as long stem lengths that help to minimize the risk of water hammers (sudden pressure surges), that could damage equipment. Most solutions also feature divergent orifice angles to reduce downstream erosion and noise caused in the high-velocity discharge process.

Additionally, effective blowdown valves are often constructed with durable, corrosion-resistant materials like stainless steel, to help ensure they continue to perform effectively, even after repeated use in somewhat challenging conditions.

The Common Types of Blowdown Valves

Blowdown valves are usually categorized into two main types: surface (continuous) and bottom (intermittent) valves. Both options are specially suited to specific conditions and applications within boiler systems, and work in slightly different ways.

Surface blowdown values operate constantly, targeting dissolved solids and impurities that accumulate on the surface of the water in a boiler. These valves are particularly valuable in systems with high vaporization rates, where concentrations of impurities can increase quickly. By regularly removing small volumes of water from the boiler, surface blowdown valves prevent scaling and keep water chemistry within safe limits.

In many cases, to optimize efficiency, surface blowdown systems are integrated with flash tanks, which capture the heat from discharged water, repurposing it for preheating feedwater, and other uses. Flash tanks can also ensure the safe cooling and disposal of blowdown water, helping buildings to adhere to safety and environmental standards.

An intermittent blowdown valve, on the other hand, operates periodically, discharging water and heavy sludge that settles at the bottom of a boiler. This sludge is often made up of sediment and undissolved solids, which, if left unchecked, can cause blockages, corrosion, and efficiency issues.

Because intermittent blowdown valves rapidly release high-pressure water, they’re often used more sparingly, to avoid sudden drops in the boiler water level of a system that could cause disruptions. After each cycle, they ensure a tight shut-off to maintain pressure and prevent leaks.

Since they’re frequently exposed to high-temperature and high-pressure conditions, bottom blowdown valves need to be constructed with durable systems, like stainless steel, and other corrosion-resistant alloys, to enable consistent performance.

How to Choose the Right Blowdown Valve for Your Boiler

Choosing the right blowdown or blow off valve for your system is crucial to maintaining efficient and consistent boiler operations. The best option for you will depend on a number of factors such as:

- Boiler Size and Capacity: Larger boilers with higher operating pressures may require robust bottom blowdown valves to handle heavy sludge, while smaller systems may only need surface blowdown valves for dissolved solids.

- Operational Requirements: Boilers with high vaporization rates benefit from continuous surface blowdown valves to regulate water chemistry. Systems with intermittent needs for sediment removal should use bottom blowdown valves.

- Water Quality: Hard water or feedwater with high levels of dissolved solids may require continuous blowdown, while systems with moderate impurities can use intermittent blowdown solutions.

When you’re making your decision, it’s a good idea to ensure your valves integrate seamlessly with your boiler’s current setup. Look at factors like material compatibility, connection types, and pressure ratings to ensure you’re making the right decision.

Expert guidance from a specialist in the boiler industry, like DB Sales, can help you make the right choice. Our team can guide you through the process of choosing a valve that matches the needs of your specific boiler and commercial environment, and adheres to industry standards.

Plus, the DB Sales team can install your blowdown valve for you, minimizing the risk of leaks and improper operation. We can even provide long-term maintenance support, to help expand the lifespan of your system, and minimize the risk of costly repairs.

Choosing the Best Blowdown Valve for Your Boiler

A boiler blowdown valve is an indispensable component in ensuring the safety, efficiency, and longevity of boiler systems. Choosing the right blowdown valve means thinking carefully about not just system compatibility, but the solution that will help maximize the lifespan of your system.

If you’re unsure which type of boiler blowdown valve is right for your commercial or industrial property, DB Sales is here to help. We can help you identify the perfect solution for your specific needs, and handle everything from installation to long-term maintenance.

Contact the DB Sales team today for a custom quote, or for more information about our blowdown valves and boiler accessories.