Steam generators have experienced a wave of mechanical and structural perfection recently, with most modern models having smarter and sustainable designs, above-average energy-efficiency ratings, and superior steam generation speeds. Applied extensively in Southern California commercial and industrial settings, modern steam generators have terrific electricity-to-steam conversion rates of 97%.

The perfect steam generation system design can beef up steam output, keeping operational costs low for you to optimally exalt your vessel heating, distillation, HVAC, or sterilization processes.

System Design

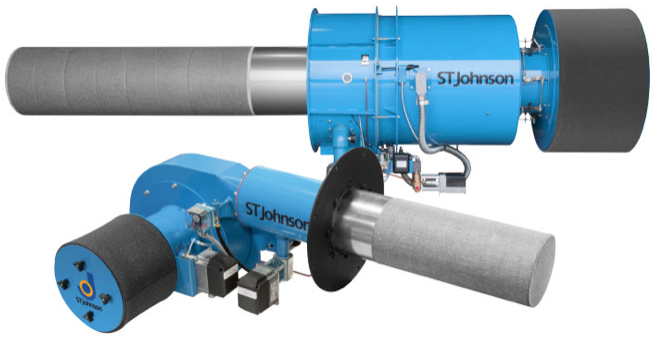

Factoring in the economic and technical factors, designing high-pressure steam systems needs precise assimilation of changeable steam generation networks capable of immaculately accommodating increasing variable-output renewables at varied capacity levels. Superior steam generation system designs blend high-performance axial airflow burn designs with high-end ultra-low aerodynamics.

High-pressure steam generation systems employ the modernized variable speed blower packages with the finest mechanical features to offer steam generation cost savings of up to 40%.

Types of Steam Generation Systems & Burners

Meeting all the California steam boiler quality requirements of at least 35 water gallons, 9.5 HP peak size, 100 square feet heating surface, and 100 PSIG relief valve point, high-pressure steam generation systems come in 2 inherently different designs:

Firetube Design

Steam generators falling in this design category come with a complete water-cooled furnace, high-efficient ratings, tight designs preventing furnace bypass, and ultra-low emission features.

Watertube Design

Watertube designed steam generators’ design is susceptible to furnace bypass and are less efficient. Hot water handling in these systems is superior to firetube designs. The solution to California’s steam generation needs is NOXmatic burners, offering superior anti-flashback devices, premium fiber mesh, and stable mixing. The NOXmatic V series burner blends capacities of up 250 boiler HP, high turndown, and 9 ppm Nox to deliver unmatched efficiency and efficient burning speeds. The NOXmatic Axial ULN burner combines heavy-duty steel housing, gas firing option, and unique swing-open design with 9 ppm Nox and up to 800 boiler HP to give the best steaming performance and efficiency.Boiler Control Types

There are different boiler control types fashioned for speedier water steaming operations.

Jackshaft controls with single-actuator, mechanical shaft, and cam have simple designs and perform optimally with higher loads.

Parallel position controls have built-in intelligence PID control functions and sole actuators for controlling the FGR, gas, and fuel. The water level control boiler options have modulating element control, tank level controller, and on/off function.

Feedwater Equipment Types

High pressure steaming generators run on high-efficient feedwater pumps, including continuous and on/off designs characterized by deaerators and atmospheric systems. California homes running on steam generation boilers with atmospheric feedwater systems enjoy reduced operational costs. The systems perform optimally in the removal of dissolved oxygen from water and have high-end atmosphere venting.

Deaerator feedwater systems come in-tray and spray options, both of which deliver a reduced thermal shock, enhanced water transmission, protective layer against oxygen pitting, and are superior when it comes to the removal of carbon dioxide and oxygen.

The push by the Californian government to introduce more sustainable and efficient industrial and household heating systems has motivated more steam generation system installations throughout Southern California. Electric steam generators have become the talk of the town, thanks to the versatility and flexibility that allows for easy integration to solar cooling and heating systems, and automated operations.

Southern California apartments and residences installed with the high-end steam generators are experiencing reduced energy costs, and footprint, coupled with high pressure and speedier steam generation and distribution for efficient completion of different projects.

Do you have plans to invest in high pressure steam generators but have no clue where to start your hunt? Contact us now for guidance and quality installations. We are California’s most trusted sales and service provider for industrial boilers, pumps, burners and more with over 40 years of experience.

Recent Comments