Regular, routine maintenance is crucial to keeping industrial and commercial steam boiler systems working effectively and efficiently. Boiler blowdown is a valuable routine maintenance procedure that can help to ensure your boiler operates consistently, year after year.

With the right strategy, a regular boiler blowdown process can optimize the performance of your system, reduce the risk of system failures, and extend the lifespan of your equipment. At DB Sales, we offer a range of services designed to improve the longevity and performance of boiler systems.

Specializing in commercial boiler sales and installation, we have extensive experience working with large commercial properties to enhance their boiler system performance, reduce maintenance requirements, and minimize carbon footprints. Read on to learn how daily boiler blowdowns can transform your business operations.

What is Boiler Blowdown?

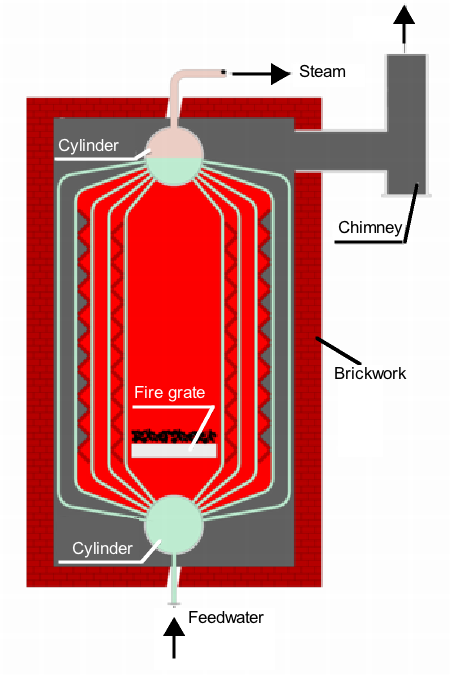

Boiler blowdown is the term used to refer to the process of removing a portion of boiler water from the system, to control the concentration of dissolved solids and impurities. The process helps to maintain effective water chemistry within the boiler, ensuring contaminant levels remain within acceptable limits, and reducing the risk of damage to the valve system.

Performing daily bottom blowdowns helps remove scale and sludge that can accumulate on the internal surface of the boiler.

Properly adjusting your surface blowdown controls the amount of TDS (Total dissolved solids inside the boiler. Running TDS levels too high can cause damage to the boiler and also cause carry over into the steam system reducing efficiency and potentially causing issues downstream.

A continuous blowdown process helps to maintain optimal boiler performance, reduces the risk of long-term boiler damage, and extends the lifespan of the equipment. It can enhance the efficiency of your boiler system, and even minimize safety risks.

The Process of Boiler Blowdown: How it Works

Though the boiler blowdown procedure is relatively straightforward, it still often requires the input of a professional team with experience using the right blowdown strategies. In most instances, the process begins with identifying the need for a blowdown. Every steam boiler needs to have blowdown performed regularly. This could mean assessing the heat recovery and performance of the boiler system, before examining the inside of the boiler system.

Building managers can monitor the concentration of total dissolved solids and impurities within boiler water. When these levels exceed the accepted range, this indicates a surface blowdown is required or the regularity of continuous surface blowdowns needs to increase.

- Gather the required PPE. This typically includes heat resistant gloves, safety glasses, hearing protection, and perhaps a face shield.

- Inspect the bottom blowdown piping. It should be in decent outside physical condition with no leaks, and properly supported to not move when stressed.

- Verify that the boiler is operating safely with the water level normal and near operating pressure.

- Verify that both valves, the quick and the slow, are closed.

- Open the quick opening valve. This will allow water to flow to the slow opening valve.

- Open the slow opening valve. As the valve is opened, the flow of the water will increase through it.

- When you have opened the valve for the proper time period (generally 10 seconds), close the slow opening valve.

- Close the quick opening valve.

- Open the slow opening valve to relieve the pressure between the two valves and then close the valve.

- Make sure both valves are seated tight and that there is no water continuing to flow from the bottom blowdown piping.

- Slowly open the blowdown valve(s) on the water level controls of the boiler. The number of valves will depend on the size and type of boiler, but it is usually just one or two valves. Make sure the boiler shuts down when the valve(s) is opened 100%, as this is simulating a low water condition. If the boiler does not shut down, secure the boiler so that it cannot operate, and have the water level control operation verified by a boiler operator/contractor.

- Record that the blowdown on the boiler was performed. There should be a chart on each boiler for tracking blowdown intervals.

Consistent and proper blowdown of a boiler helps to maintain a safe operating environment, and prioritizing this basic maintenance is vital to avoid water quality issues that will affect the boiler operation and the steam quality of the plant. Contact Boiler Specialists Inc. if you have any questions about the blowdown procedure of your boiler. We’re here if you need us to make a training program for you, or if you just need some blowdown valves for your boiler, as we stock many varieties and sizes.

The Benefits of Boiler Blowdown

the performance and efficiency of their systems. Systematically removing impurities from a boiler reduces operational costs, and enhances system performance.

The right strategy can significantly lead to:

- Greater Efficiency: Boiler blowdown improves operational efficiency, preventing scale formation, which can impede effective heat transfer. An insulating layer of scale can cause the boiler to consume more fuel to achieve the right temperatures. Removing these impurities ensures your system can continue to operate at optimal levels, without higher costs.

- Increased boiler lifespan: Regular boiler blowdown and surface blowdown strategies can help to prevent damage to your system from scale and corrosion. Scale can lead to hot spots and overheating that prompt boiler failure, while corrosion damages the metal components of your boiler, causing increased chances of leaks and failure over time.

- Cost savings: Improved boiler efficiency translates to lower energy bills. Additionally, preventing scale and corrosion can reduce the frequency and severity of maintenance issues, leading to fewer repairs and lower maintenance costs.

Talk to the HVAC Experts

DB Sales & Service will have your commercial building running efficiently in no time with our commercial HVAC solutions.

The Common Issues Addressed by Boiler Blowdown

On a broad scale, boiler blowdown addresses a few key issues that can occur within any boiler. Simply allowing a small amount of water and sediment to drain from your boiler regularly first reduces the risk of scale and sediment build-up.

Scale and sediment are caused by mineral deposits that accumulate on the internal surfaces of a boiler. Scale forms when dissolved minerals in the water precipitate and adhere to the boiler’s surfaces due to high temperatures. Sediment, which consists of heavier particles and impurities, settles at the bottom of the boiler. Both of these substances harm the performance of boilers, impeding heat transfer.

The reduced efficiency caused by scale and sediment build-up leads to an increased risk of damaged to your boiler, and higher operational costs. However, boiler blowdown helps to reduce these issues, ensuring your boiler can perform better, and last longer.

Blowdown strategies help to reduce the concentration of these impurities, allowing for control over water chemistry, minimizing the effects of corrosion.

Best Practices for Boiler Blowdown

The two most important things to keep in mind when implementing a boiler blowdown strategy is that most businesses need to conduct regular checks of their system, and work with experts to ensure they’re implementing the right blowdown methods.

Routine water quality checks, conducted to measure the concentration of dissolved solids and impurities, as well as PH levels, can help you identify the right frequency and volume for your blowdown strategies. You can adjust your blowdown schedule to constantly address changes in water chemistry, and stay one step ahead of potential damage.

Working with a professional team of boiler experts on boiler blowdown procedures, ensures you can get the best results from your process. Professional technicians are skilled in assessing water quality, determining the right blowdown parameters, and executing the process safely.

Our team can help train your staff on daily boiler blowdowns to ensure energy efficiency and a low energy bill.

DB Sales Boiler Services

As experts in HVAC and boiler system installation and maintenance, DB Sales offers a range of services to commercial organizations. We specialize in boiler sales and installation, designing and configuring custom boiler systems, tailored to the specific needs of commercial properties.

Our extensive range of services include:

- Boiler sales and installation: Our team of experienced technicians and engineers implement boiler systems, carefully tuned to ensure optimal performance for your organizations. We’ll help you choose the boiler solution best-suited to your specific needs, and implement the right technologies to improve performance metrics and optimize efficiency.

- Boiler maintenance and repairs: We’re committed to ensuring your boiler systems last as long as possible. Our team offers comprehensive services for boiler repair and maintenance, ranging from emergency repairs, to regular maintenance solutions, specifically designed to fit your business needs. We only ever use the highest-quality parts and components from top industry brands, to optimize the performance and lifespan of your boilers.

- Low NOx burners: We can also offer access to low NOx burners, which can reduce nitrogen oxide emissions, making your boiler more energy-efficient and environmentally friendly, helping you to achieve your sustainability goals and reduce operational costs. These eco-conscious solutions not only reduce costs, but help you to comply with the latest environmental regulations in your industry.

Whatever your requirements might be for boiler installation, maintenance, and optimization, DB Sales can ensure you achieve your business goals, and keep costs low, while protecting the environment.

Protect your Boiler’s Longevity with Boiler Blowdown Services

Boiler blowdown services form a fundamental part of a comprehensive strategy for boiler maintenance. With regular blowdown services, you can ensure your boiler systems continue to operate at peak performance for as long as possible.

Not only do these services reduce the strain on your system, leading to reduced risk of damage and failure, but they can also significantly reduce your operational costs, and improve your environmental footprint – particularly when combined with other maintenance strategies.

By controlling impurities in your boiler water, you can boost your chances of accessing a powerful boiler system that continues to perform with exceptional efficiency year after year.

Learn more about how you can improve the lifespan and performance of your boiler with expert installation, configuration, and maintenance support from DB Sales.

Contact our team today for an initial consultation and assessment.

Lower Your Utility Bills With DB Sales & Service

Talk to our commercial building boiler experts today.

Recent Comments