Manufacturers Have 2 Different Ways of Getting Their Products Listed

- ✓ ANSI Z21 – Categorized appliances that include gas-fired low-pressure steam and hot water boilers

- ✓ UL795 – Building heating appliances including commercial-industrial gas heating appliances

2 Factors When Deciding on Appropriate Venting Categories

There are 4 different categories of boiler venting applications. There are two main factors you need to take into consideration when choosing the appropriate category for your needs.

The first factor is positive or negative pressure. Negative pressure is anything being pulled out of the appliance and positive pressure is anything being pushed out of the appliance.

The second factor is condensing or noncondensing. If your boiler is listed 85 and below then you’re most likely going to be classified as non-condensing which means you can get away with categories 1 and 3. If your boiler is listed at 85 and above you’re going to be in condensing mode.

Be Aware of Restrictions

We use two handbooks when sizing gas appliance vents. The NFPA handbook tells us what we can and can’t do, while the ASHRAE handbook tells us how to do it. For instance, PVC is not listed for venting applications because heat changes the molecular structure making the material extremely brittle. However, most stainless steels and polypropylene are listed for venting applications. Different categories of venting systems have different ratings for different applications.Common Vent Applications

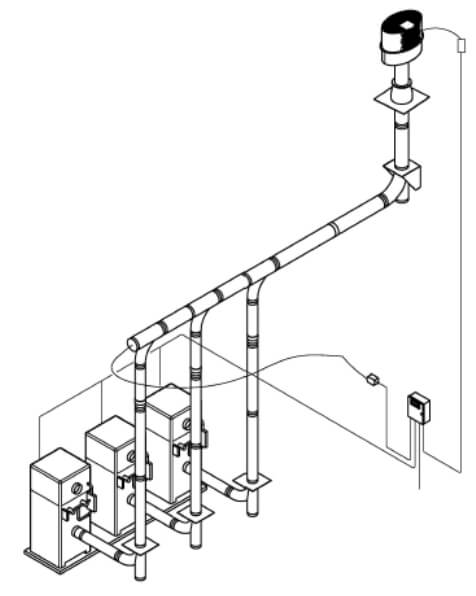

When multiple boilers run through a common space, it is a design that very few systems can handle. This is where DB Sales comes into play. We offer 3 different U.S. Draft Co fans to help alleviate this issue. One of our fans, our TruLine Fans, are authentic inline fans that are ideal for retrofits and capable of being installed on systems without an offset. We offer 11 models to accommodate a variety of designs.Overdraft

Overdraft typically happens when there are huge variances in temperature or when the boiler has been running for a long period of time and is on the downside of its cycle. Our OBD – Draft Control Damper offers a solution for controlling overdraft. It features a multi-blade opposed blade damper, programmable fast-acting actuator, and two auxiliary switches.Controllers

We proudly offer next-level control systems for boiler systems by U.S. Draft Co. Our state-of-the-art controllers can read + or – one inch. This means we see the spike in pressure and are able to react 50-60% faster than other controllers. For instance, on a common vent system, you have three boilers. The far-left boiler is running great. Then the master controller says there is a need for more heat, so a signal is sent to the middle boiler. It begins its pre-purge cycle which blows a bunch of cold air into the stack. This changes the volume, temperature, and pressure. The pressure spikes 1/2 an inch but the controller can’t detect or respond to changes that small. It creates a blockage. The back-up switch recognizes the blockage and shuts the first boiler off. The second boiler continues to pre-purge and fire. The master controller still calls for more heat and signals the third boiler and the cycle continues. Now all of a sudden you have cycling boilers. There are three ways you can overcome it:- ✓ You can oversize the system

- ✓ Create a deeper negative

- ✓ Simply use a controller that can detect even the smallest pressure changes and react accordingly

- ✓ Integrated EC-Flow technology

- ✓ Bi-directional differential pressure transducer

- ✓ High and low safety functions

- ✓ Fully field programmable with adjustable settings

- ✓ Touchscreen

Recent Comments